- +55 11 98173-9164 financeiro2@g4maquinas.com.br

700/ 850/ SM/ SR/ TR

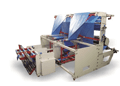

Line of compact machines for the manufacturing of shirt-type bags and disposal bags. The best cost-benefit for your production, completely automatized, controlled by PLC and Servomotor. We have the most advanced technology, low maintenance and easy handling. With several optional resources, the START 700/850.

Line of compact machines for manufacturing t-shirt bags and garbage bags. The best cost-benefit for your production, fully automated, controlled by PLC and Servomotor. We have the most advanced technology, low maintenance and easy handling. With several options, the START 700/850 has everything you need to start or complement your industry with quality.

Automatic machine for the manufacturing of conical packaging of the types vegetable and fruits, flower pots, flower bouquets, etc.

Line of compact machines for manufacturing bags (bottom welding) and t-shirt bags. The best cost-benefit for your production. Machine model supplied without the accordion tower, with the customer needing to supply the machine with individual coils with or without accordions.

Line of compact machines for the manufacturing of shirt-type bags and disposal bags. Machine start 700 complete with automatic robot for pressing of the handles.

MODELS: 700 | 850 | 1100 | 1300 | Special

Basic machine for high production of bottom-welded packaging, garbage bags, liner packaging, refrigerated bags, and others. They can be adjusted in 1, 2 or 3 tracks, and can also be adjusted with a side welding head and silicone roller.

Machine for high production of bottom welding packaging, with stacking table, garbage bags, liner packaging, refrigerated bags, and others. They can be configured in 1, 2 or 3 lanes, and can also be configured with a side welding head and silicone roller.

Complete high-speed bagging machine, which can be configured with an electrode head or nickel chromium ribbon, with mechanical carbon fiber detacher, available in 2,3,4,5 or 6 lanes.

Line of more robust machines for large-scale production of heavier and wider deep welded bags. It can be configured with different options for manufacturing different types of packaging.

Highly efficient and versatile block bag manufacturing solution. Developed to meet the needs of the supermarket and fruit and vegetable sector, our machine is capable of producing block bags with up to 6 lanes, as well as sandwich bags and a variety of other flexible packaging models. Ideal for packaging fruit and vegetables that require high quality packaging. Whether for packaging fresh products on supermarket shelves, or for application in fruit and vegetables, our machine offers solutions adapted to your needs. It allows the production of precise block bags, with excellent resistance and sealing, guaranteeing the integrity of the packaged products.

Machine line for manufacturing linear type bags. It has a tangential brake for greater film tension control and has a presser to hold the film (does not pierce the film).

Machine for manufacturing star bottom type perforated coils, with a useful roll width of up to 150mm, working with 1 track, high speed machine, which can be configured with 1 side triangle or double rear triangle, came to revolutionize the perforated coils market in the Brazil, lots of technology and low maintenance.

Machine line dedicated to the manufacture of perforated star bottom coils (fruit and vegetable products). It has an accordion tower allowing the accordions to be made in the perforating machine and not in the extruder. In addition, it has 1 triangle to perform the fold.

Machine for manufacturing perforated coils for use in laundries. Maximum useful width of 900mm, working with 1 track, high-speed machine, came to revolutionize the market for perforated coils in Brazil, lots of technology and low maintenance.

Machine for manufacturing perforated coils. Maximum useful width of 900mm, working with 1 track, high-speed machine, came to revolutionize the market for perforated coils in Brazil, lots of technology and low maintenance.

Shredding machine for manufacturing roll garbage bags or cushion garbage bags, with star bottom or flat bottom, machine with electric expanding drum, with greater ease and agility for changing measurements, with 3 changing stations and attached automatic labeling machine.

Perforating machine for manufacturing rolled garbage bags or cushion garbage bags, with star bottoms or flat bottoms, machine with electric expanding drum, with greater ease and agility for changing measurements, with 3 changing stations and attached automatic labeling machine.

Models: 700/900/1100/1400

Belt Cutting and Welding Machine for the production of various plastic packaging, which can be configured for edge welding, bottom welding and side welding, high production machine and controlled by PLC and Servo Motor, support for different devices according to the need customer requirements, available in widths 700/900/1100 and 1400. Packaging in small sizes, side weld bags, KG bags, food packaging, etc.

Models: 700/900/1100

Belt cutting and welding machine for the production of plastic packaging. This version of the machine has a “bag” type welding head intended mainly for the food industry. The machine has the option of being manufactured and delivered with several heads (longitudinal pocket head, cross bag, PP side welding head and PE side welding head).

Models: 800/1000/1200/1600/2000

iFlex-C Flexographic Printer Model, available in widths of 800/1000/1200, configurable with 4, 6, and 8 colors. A robust machine with a cast iron structure and equipped with advanced construction technology, with a thickness of 80mm. Its printing unit features a modern electronic advance/retraction system with automatic relief. Anilox and sleeve holder devices are moved through linear guides and spherical spindles. Plate cylinder with onboard sleeve change system performed inside the machine and Zero Gap system, integrated PLC with HMI equipped with a 10-inch color touch screen. Mounted in a cabinet with an ergonomic operating panel, with main command functions activated on the screen and easy operation. For adjustment and operation near the printing group, the iFlex-C has 02 7-inch color touch screen HMIs.

iFlex S Flexographic Printer Model, available in widths of 1200/1600/2000, configurable with 4 and 6 colors. A robust machine with a cast iron structure and equipped with advanced construction technology. Its printing unit features a system of advance/retraction of the anilox and sleeve holder through a motorized threaded bar to facilitate advancement and with automatic relief. It allows fine adjustment of printing through its color knobs. Plate cylinder with sleeve change system performed outside the machine and Zero Gap system, integrated PLC with HMI equipped with a 10-inch color touch screen. Mounted in a cabinet with an ergonomic operating panel, with main command functions activated on the screen and easy operation.

We have a huge stock of spare parts for cutting and welding machines, as well as offering specialized services with qualified and always up to date professionals.

We create accessories for the best performance and productivity of your equipment.

Accessory used for simultaneously cutting and soldering the film, separating the plastic film coil into several lanes.

Developed to grant an appearance of micro points (micro holes) on the bag

Accessory used on machines for cutting and soldering G4 to bend the material into 2, 3 or 4 parts for packaging of the type “star bottom”.